Biogas, the energy of the future

Biogas plants provide a storable and renewable energy source while also dealing with local waste management

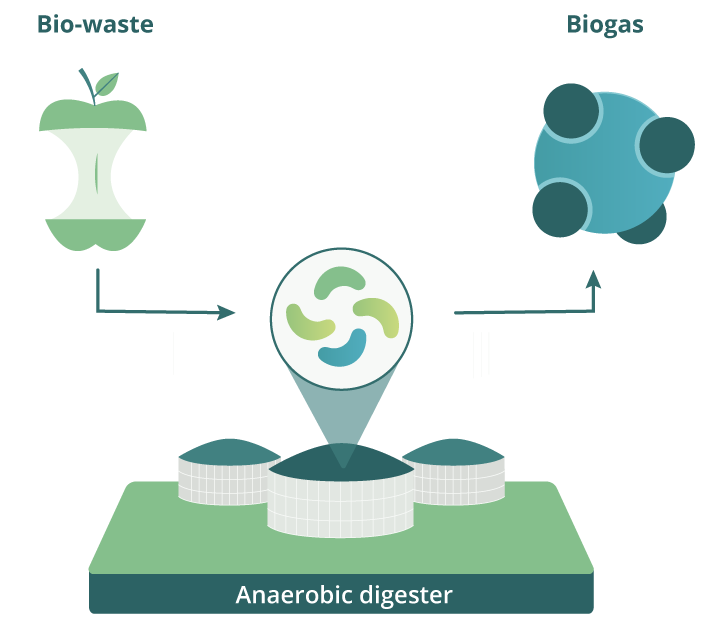

Biogas is a mixture of methane (CH4; 55–70% of the total volume), carbon dioxide (CO2; 30–40%) and traces of other gases. It is obtained through the anaerobic digestion (AD) of organic matter, a process carried out by various species of microorganisms in close collaboration, and it is produced inside anaerobic digesters. Industrial AD has two advantages: the production of biogas that can be used as vehicle fuel or to generate electricity or heat, and the treatment of organic waste such as sewage sludge, animal slurry and food waste.

Making biogas production efficient

Our ambitious objective at MICRO4BIOGAS is to optimise the biogas production process

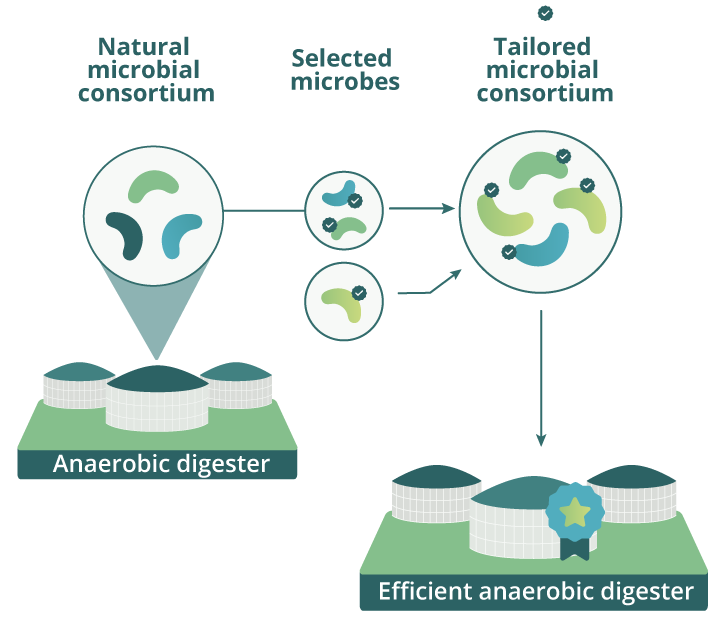

We use bioaugmentation strategies based on microbial strains that naturally inhabit production tanks. We will select the most efficient microbes and combine them with artificial microbial consortia, developed through kinetic modelling, flux balance analyses and adaptive evolution. This way, we aim to improve the yield, quality, speed and robustness of biogas production. Our work at MICRO4BIOGAS is well aligned with the EU Bioeconomy Strategy and the European Green Deal.

Milestones

Work packages

MICRO4BIOGAS is divided into eight work packages (WPs) which deal with four topics.

Foundations of the bioaugmentation strategy

We will deeply analyse the European biogas landscape from several points of view, including technological and innovative aspects as well as policy considerations. Indeed, we will isolate, characterise and improve microbial consortia that naturally inhabit anaerobic digesters. All these results will be integrated and fed into the following WPs, the main goal of which is to develop a novel bioaugmentation strategy.

Validation, scale up, and exploitation of the bioaugmentation strategy

We will perform several proof-of-concepts in different scale and configuration reactors, characterising biogas yield, quality, residence time and robustness of the process. In addition, we will evaluate the environmental life cycle and technoeconomic aspects of the and develop a business model for its future exploitation.

Communication and management

We will maximise the impact of MICRO4BIOGAS by raising awareness through communication and dissemination, as well as providing professionals working in AD digestors with training activities.

We will ensure an effective realisation and management of the project activities whilst ensuring the smooth development of all aspects of the project.