With the recent rise in gas prices and the need to increase sustainable energy production, biogas has become a key player in the European energy market. But its production is not optimised yet. Yield, speed, and even the quality of biogas rely on the microorganisms that naturally live inside anaerobic digesters, fermenting organic materials and producing renewable fuel. To turn biogas into a reliable and efficient energy source, we need microbiomes that can deliver predictable results.

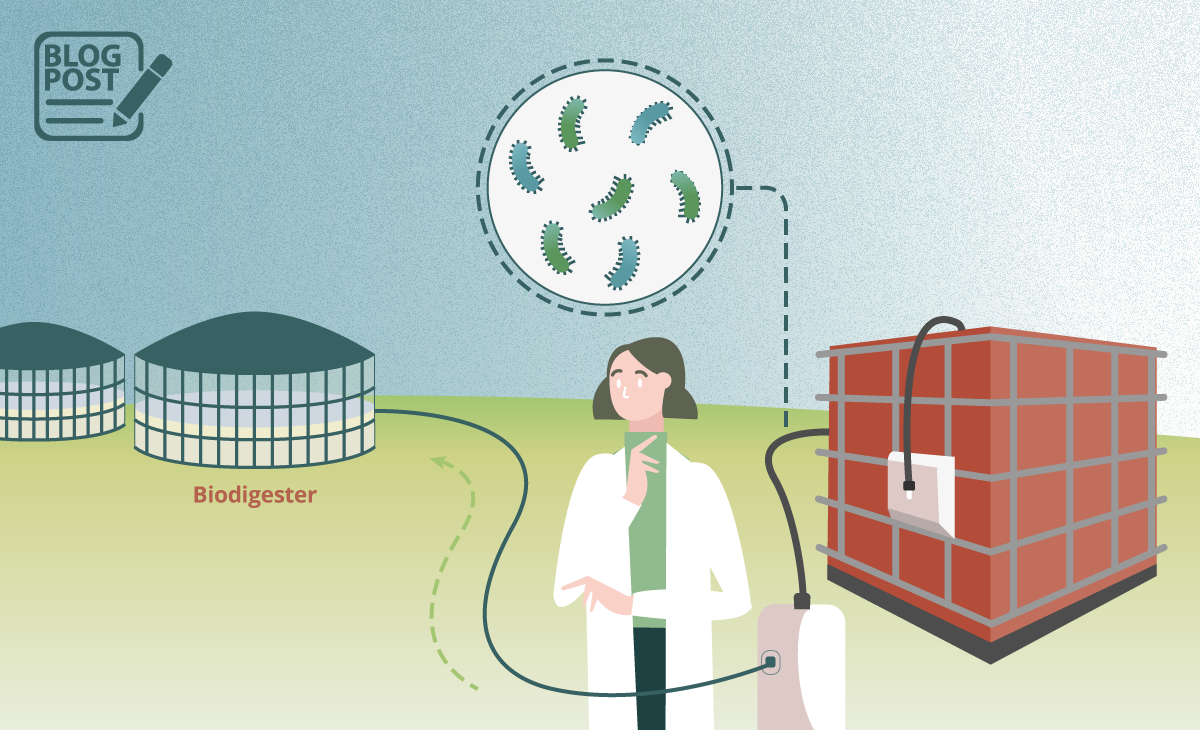

At Micro4Biogas, we study and manipulate microbial communities to increase biogas production. The make-up of these complex microbiomes varies depending on factors such as location and the substrates available to feed the biodigesters. In many cases, the most efficient microbes are already present – but not always. When microbial communities need improvement, how can we manipulate them and boost biogas production?

Perfecting the mechanisms of microbial degradation

Our partners at BioClear Earth are trying to figure this out using a technique called bioaugmentation. They have more than 30 years of experience in this, studying soil contamination and promoting the breakdown of pollutants by adding the right bacteria to improve performance, and creating the perfect conditions for these to grow. “A strategy that can also be used in bioenergy production,” says Jeroen Tideman, team manager for innovation & technology at BioClear Earth.

Anaerobic digestion is a process through which bacteria break down organic matter, but even though the microbial communities that produce biogas have been characterised, this complex system is not well-understood. “The first step is zooming in, to learn how this works, the relations between process conditions and the bacteria that are present, and which are the best performing biodigesters. If we can understand these relations, we can improve the process,” says Tideman.

In search of a universal solution

BioClear’s experience in bioaugmentation is key to develop a single solution that is effective for the majority of biodigesters. “We are working on performing the right tests to understand the relation between different species, and to guarantee that introduced microbes won’t be pushed out. Besides, we also need to learn how to grow species that are difficult to culture in the lab,” Tideman explains.

Studying samples from 80 biogas plants, Tideman’s team has found “that there is a core microbiome, a group of species that is always there. The further you move along the digestion process the more the communities from different biodigesters resemble each other”. Stimulating the growth of this core microbiome or introducing these species in biodigesters that do not contain them is one of the strategies outlined in Micro4Biogas.

But the ultimate goal is divided into three steps related with common bottlenecks of anaerobic digestion.

“We will study how to improve the degradation of fibers, like cereal straws or forest residues, a promising substrate that does not compete with food production,” Tideman explains. “But we are also looking for ways to increase the speed and robustness of the fermentation process, to produce more biogas. In addition, we’ll try to improve the methanation, a step that will allow us to increase the amount of material we can feed into a biodigester.”

In alignment with the goals of the European Commission to increase biogas production in European countries to a volume of 20% of current Russian gas imports, Tideman believes his team’s contribution to Micro4Biogas will have a massive impact on the biogas sector. “The challenges are complex, the risk is high, but so is the reward,” he says.